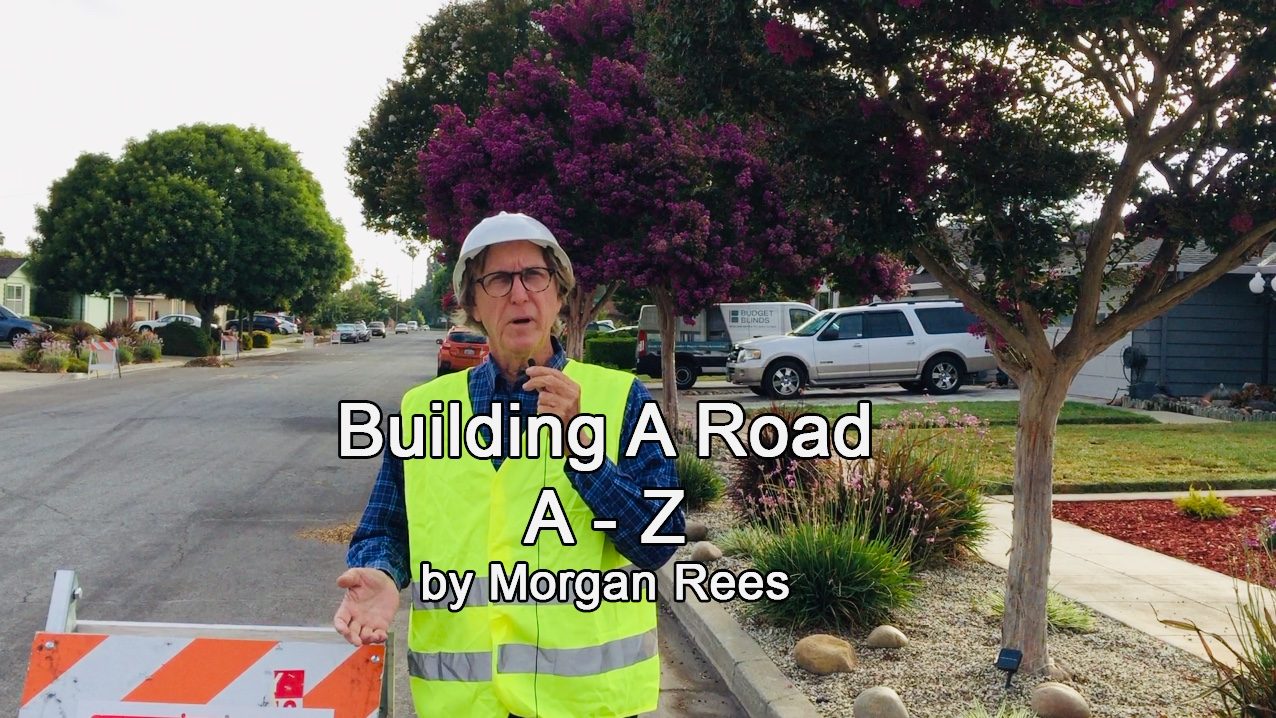

It’s amazing how much planning, work, and science goes into something like a road that we drive over every day?

During the road-building process, workers will spread and compact over 300-degrees asphalt on the roadbed.

Fortunately, technologies like GPS and laser surveys have improved accuracy and made this significantly easier.

Hope you enjoy watching “Making A Road” by Morgan Rees (Only 4-minutes)

The Complete 7-Step Process for Asphalt Pavement Installation

Step 1: Demolition and Removal. …

Step 2: Grading and Sloping. …

Step 3: Prepare the Sub Base. …

Step 4: Proof Roll, Undercutting and Sub Base Repair. …

Step 5: Binder and Surface Course. …

Step 6: Install New Asphalt Surface. …

Step 7: Butt Joints and Transitions.

Did you know that making asphalt is kind of like baking a cake? You need the right amounts of the proper ingredients, and then you need to mix them and heat them up!

The center of the roads will be higher than the edges so that water will run off into the storm sewers.

Fortunately, technologies like GPS and laser surveys have improved accuracy and made this significantly easier.

While you’re surveying the land, be sure to keep the following factors in mind.

* Location

* Terrain and soil properties

* Drainage capabilities

* Traffic volume

* Ratio of cars to trucks and buses

* Possible future development in the area

* Effects of the environment or nearby residents

The best way to understand the cost to build a road is to speak with a professional. Each project is unique, and the price will depend on the size, materials use, amount of labor, etc.

Once you’ve determined a budget, be sure to add an additional 10 to 15 percent buffer for any unforeseen additions to your project.

If you’re struggling to understand what your money could be going to, here’s what you should be considering.

Permits

Excavation

Engineering

Gravel

Erosion control

Rebar

Concrete

Asphalt

Pavers

Culverts

Asphalt uses a petroleum product called bitumen to glue together the sand and crushed rock.

This mixture is heated to approximately 300 degrees as the asphalt plant.

During the road-building process, workers will spread and compact over 300-degrees asphalt on the roadbed.

Concrete mixes cement and water to make a glue to place between the sand and crushed rock.

Construction workers will place concrete into steel molds called forms.

A finishing machine will vibrate and trim the concrete to the necessary height.

If you design your road with winter maintenance in mind, then it will hold up well during the winter as well as the other seasons.